Although it normally takes a skilled worker to program and build a CNC lathe, running one particular is fairly very simple. Firms can assign an entry-degree worker to change parts even though their experienced (plus more highly paid out) personnel are engaged in responsibilities commensurate with their skills.

Parts with intricate designs or limited tolerances have to have slower machining speeds, which could maximize production time and price. As an example, a relatively easy turned element could Charge inside the double digits, even though extra complex parts could possibly cost from the hundreds.

Peter Jacobs is definitely the Senior Director of selling at CNC Masters, a number one supplier of CNC mills, milling machines, and CNC lathes. He's actively associated with manufacturing procedures and often contributes his insights for different weblogs in CNC machining, 3D printing, immediate tooling, injection molding, metallic casting, and manufacturing generally speaking. You'll be able to hook up with him on his LinkedIn.

On some CNC turning centers, a bar feeder moves the bar inventory as Every turned aspect is completed, while some have live tooling. This flexible characteristic allows for milling or adding radial or axial holes without taking away the workpiece through the CNC lathe.

Set and conserve your 0.00 posture about the machine. These coordinates will likely be recorded as the 1st line of the program within the Editor Monitor. Should you desire to return to this plan in a afterwards day, you only have to click on the Set Zero Return button.

You need a thing that received’t cripple your finances but will give the flexibility and ability you might want to increase your online business. Consider our line of very affordable CNC mills.

It’s an embodiment of technological evolution, marrying the age-previous rules of the lathe machine with advanced computer programming to obtain unparalleled accuracy and efficiency in machining.

Whether you are hunting for a small CNC lathe with live tooling, or a typical two-axis machine, MAZAK may have you lined.

A CNC lathe can be an assembly of intricate components, Each and every participating in a vital part in its Procedure. Being familiar with these components offers you a deeper Perception into how these machines accomplish these kinds of high levels of precision and efficiency. In this article’s a breakdown of the key parts:

Picking out the suitable chopping parameters for example chopping speed, feed charge, and depth of Minimize based upon the fabric and ideal result.

Strengths: Gravity helps to secure the workpiece, reducing the need for comprehensive clamping. Delivers far better access to the workpiece for particular operations.

Also, the enclosures appreciably reduce the threat in the course of machining, because the staff are not likely subjected to any shifting components, Read more controlling anything needed from a video display.

The principle difference lies from the motion on the workpiece, with CNC turning excelling in creating cylindrical parts and CNC milling giving a broader range of opportunities for complex geometries.

Warm Keys is an alternate process to easily control your machine using your tough or touch monitor keyboard.

Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Judge Reinhold Then & Now!

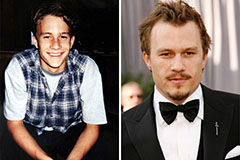

Judge Reinhold Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Ryan Phillippe Then & Now!

Ryan Phillippe Then & Now!